In the intricate world of industrial components, the "Flat Rubber Ring" has emerged as a crucial element across multiple applications. Industry expert Dr. John Harper, a renowned engineer specializing in sealing technologies, once stated, “The versatility and reliability of flat rubber rings make them indispensable in various mechanical systems.” This statement underscores the importance of understanding not only what flat rubber rings are, but also their diverse uses and benefits in today's manufacturing landscape.

Flat rubber rings, which are often used as seals or gaskets, provide a vital function in preventing leaks and maintaining pressure in systems ranging from automotive engines to household appliances. Their design allows for an effective seal that can withstand considerable temperature and pressure variations, making them highly effective in numerous environments. As more industries recognize their value, a comprehensive guide on their uses, advantages, and purchasing considerations becomes essential for engineers and consumers alike.

This article aims to delve deeper into the specifics of flat rubber rings, exploring their diverse applications, benefits, and what to look for when buying them. With insights from industry experts and practical information, readers will gain a clearer understanding of why the flat rubber ring remains a reliable choice in today's mechanical world.

Flat rubber rings, commonly known as rubber gaskets, play a pivotal role across various industries due to their unique properties and versatility. These rings are engineered to create a seal between two surfaces, preventing the leakage of liquids or gases, which is crucial in numerous applications ranging from automotive to plumbing. Their ability to withstand extreme temperatures, pressure, and exposure to different chemicals makes them essential components in machinery and equipment, providing reliability and safety.

In the automotive industry, flat rubber rings are used in engines and fuel systems to ensure secure seals that prevent leaks and contamination. In plumbing, they are instrumental in fixtures and pipes, offering a barrier that stops water from escaping. Additionally, in the manufacturing sector, these rings are vital in equipment where maintaining cleanliness and minimizing contamination is critical, such as in food processing and pharmaceuticals. The adaptability of flat rubber rings to various environmental conditions and their cost-effectiveness make them indispensable in modern industrial applications.

| Dimension | Material | Use Case | Benefits | Typical Industries |

|---|---|---|---|---|

| 10 mm x 2 mm | Nitrile Rubber | Sealing applications in automotive | Excellent oil resistance | Automotive, Machinery |

| 20 mm x 3 mm | Silicone Rubber | Food processing equipment | High temperature resistance | Food & Beverage, Pharmaceuticals |

| 15 mm x 1 mm | EPDM Rubber | Gaskets in plumbing | Excellent weather ability | Construction, Plumbing |

| 25 mm x 5 mm | Natural Rubber | Shock absorption in machinery | Good elasticity and resilience | Manufacturing, Engineering |

Flat rubber rings, commonly used for sealing and insulation purposes in various industries, are manufactured from a range of materials, each offering distinct properties suited to specific applications. Natural rubber, known for its superior elasticity and tear resistance, is commonly employed in environments where flexibility and durability are paramount. In contrast, synthetic rubbers like nitrile (NBR) and neoprene are favored in applications where chemical resistance is critical, such as in automotive and industrial settings. According to a report by MarketsandMarkets, the global rubber seals market is projected to reach $12.4 billion by 2025, reflecting the high demand for reliable sealing solutions across various sectors.

In addition to these materials, specialized formulations, such as fluorosilicone and EPDM (ethylene propylene diene monomer), are utilized for high-temperature applications and environments exposed to ozone or weather elements. A thorough understanding of the properties of these materials can significantly impact the performance and lifespan of flat rubber rings. For instance, materials like EPDM demonstrate excellent resistance to heat, steam, and weathering, making them ideal for outdoor applications.

Tips: When selecting a flat rubber ring, consider the operating temperature and the presence of chemicals to ensure compatibility with the environment. Additionally, purchasing from reputable suppliers can guarantee material quality and adherence to industry standards, which is crucial for ensuring optimal performance and safety in applications.

This bar chart represents the percentage composition of various key materials used in the manufacturing of flat rubber rings. The most common material is NBR (Nitrile), followed by EPDM, SBR, Neoprene, and Silicone.

Flat rubber rings, commonly known as washers or gaskets, play a crucial role in various industrial applications. Their design allows them to provide a tight seal between surfaces, preventing the leakage of fluids and gases. One of the most prevalent uses of flat rubber rings is in piping systems where they are employed to secure joints and maintain integrity under pressure. This is particularly vital in industries such as petrochemicals and water treatment, where even minor leaks can lead to significant operational challenges and safety issues.

In addition to sealing applications, flat rubber rings are also used in electrical and mechanical assemblies. They act as spacers and provide insulation, protecting against vibrations and temperature fluctuations that can damage components over time. In automotive manufacturing, for example, these rings are essential in securing parts of engines and transmission systems, contributing to overall efficiency and safety. The versatility and reliability of flat rubber rings make them indispensable across a wide range of industrial settings, where they enhance performance and reduce the risk of equipment failures.

Flat rubber rings, often referred to as sealing rings or gaskets, are invaluable components in various applications due to their unique properties. These rings are designed to provide an airtight and watertight seal between surfaces, making them essential in plumbing, automotive, and industrial machinery. The elastic nature of rubber allows these rings to compress and conform to the surfaces they are sealing, effectively preventing leakage of fluids or gases. This capability not only enhances the performance of products but also extends their lifespan by reducing corrosion and wear caused by environmental factors.

In addition to their sealing properties, flat rubber rings also provide excellent insulation. They help minimize thermal conductivity, which is particularly beneficial in systems where temperature control is crucial. For example, in HVAC installations, flat rubber rings can reduce energy loss by ensuring that joints remain sealed and insulated. This functionality leads to increased energy efficiency and lower operational costs. Furthermore, flat rubber rings are resistant to various chemicals, which increases their versatility across different industries while ensuring reliable performance in challenging environments.

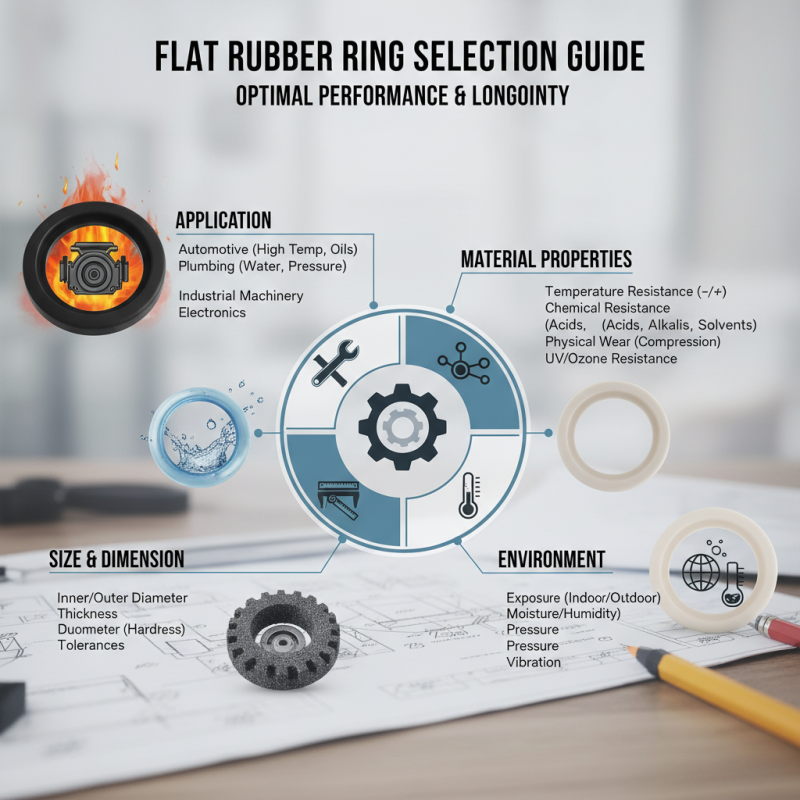

When choosing the right flat rubber ring, several factors should be taken into consideration to ensure optimal performance and longevity. First, you need to assess the intended application of the rubber ring. Different applications can demand specific properties such as resistance to temperature extremes, chemicals, or physical wear. For instance, if the ring will be used in automotive applications, it may need to withstand higher temperatures and certain oils, while a seal in plumbing may require a different type of resistance.

Additionally, sizing is crucial. Accurate measurements of the inner and outer diameter, as well as the thickness of the ring, are necessary for a proper fit. A ring that is too large may fail to seal effectively, while one that is too small can become overstressed and fail prematurely. It is also important to consider the hardness of the rubber, as this can impact elasticity and overall functionality. Consulting with technical specifications or seeking advice from experts can help navigate these choices for the best possible outcome in your application.