A Force-Sensitive Resistor (FSR) is an essential component in the realm of electronics, particularly known for its ability to detect and respond to applied pressure. These versatile devices operate on the principle of changing resistance in reaction to mechanical force, making them invaluable in a variety of applications, from simple tactile switches to intricate robotic sensors. Understanding the mechanics of an FSR is crucial for engineers and hobbyists alike, as it opens the door to innovative designs and creative solutions across numerous fields.

In this exploration of force-sensitive resistors, we will delve into their operational principles, highlighting how they convert mechanical pressure into an electrical signal. We will also examine their various applications and the advantages they bring to electronic projects. By grasping how FSRs function, we can better appreciate their role in advancing technology, facilitating the development of responsive and interactive electronic systems. Whether used in wearable devices, smart home technology, or automotive sensors, the significance of force-sensitive resistors continues to grow, paving the way for the future of responsive electronics.

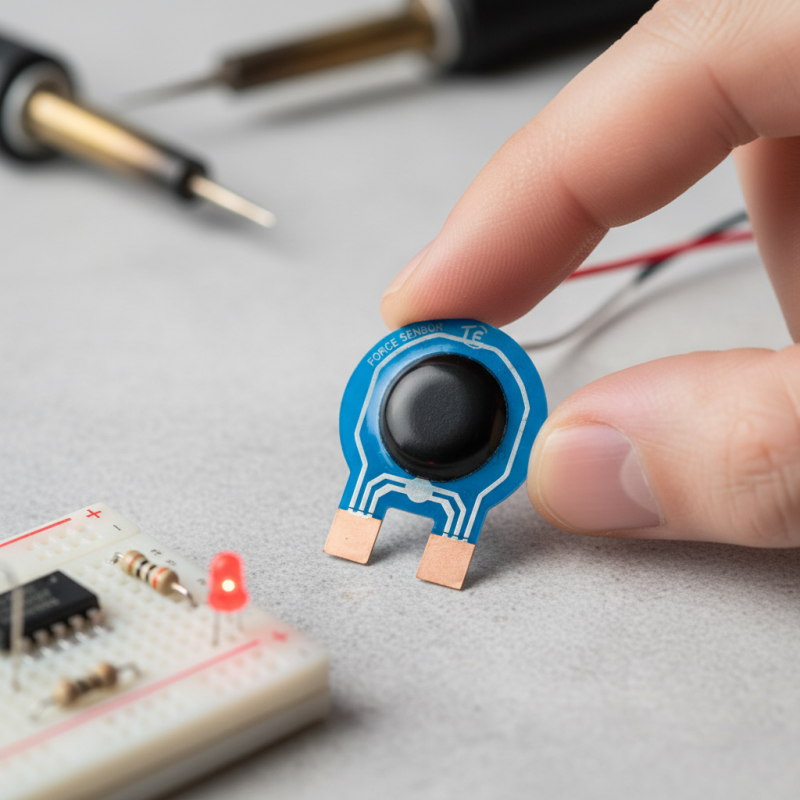

A Force Sensitive Resistor (FSR) is a type of sensor that changes its resistance in response to the amount of force or pressure applied to its surface.

These resistors are made of a conductive material that becomes less conductive as the pressure increases, allowing for variable resistance readings. Essentially, an FSR is an analog sensor used to detect physical force, making them essential in various electronic applications such as robotics, audio equipment, and gaming devices.

One of the key advantages of FSRs is their simplicity and ease of integration. They are commonly used in tactile buttons, pressure pads, and even as part of larger sensor systems. When an FSR is connected to a microcontroller, it can provide real-time feedback on pressure changes, which can be invaluable for applications that require user interaction.

Tips: When using FSRs in your projects, ensure you calibrate them for accurate readings. Consider the maximum force the sensor can handle and perform tests to understand its response curve. Additionally, remember to implement filtering or averaging techniques in your code to achieve more stable readings, especially in environments with varying pressures such as vibration or movement.

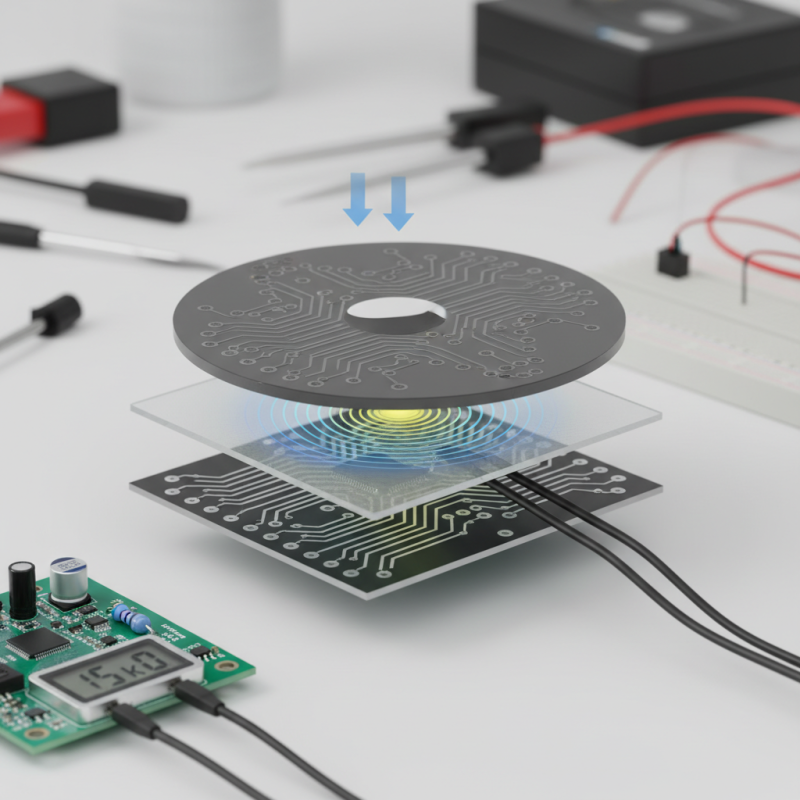

Force Sensitive Resistors (FSRs) are unique components in electronics that change resistance in response to applied pressure, making them highly valuable in various applications, from robotics to consumer electronics. The principle behind their operation is quite straightforward: FSRs consist of a conductive material sandwiched between two layers of insulating material. When pressure is applied to the sensor, the conductive particles within the FSR come into closer contact, reducing resistance and allowing more current to flow through the component. The relationship between pressure and resistance is not linear; instead, the resistance decreases exponentially as pressure increases. This characteristic allows FSRs to provide a wide dynamic range, making them ideal for measuring different levels of force.

According to a report from the industry analyst firm Technavio, the global market for FSRs is expected to witness a compound annual growth rate (CAGR) of around 5% from 2021 to 2025. This growth can be attributed to the increasing need for touch-sensitive applications in consumer devices, healthcare, and automotive sectors. FSRs can be used in touchscreen displays, pressure-sensitive mats, and even in wearable technology, where understanding user interaction through pressure can dramatically enhance the user experience. The lightweight and flexible nature of FSRs also contributes to their versatility, as they can easily be integrated into various devices without adding significant bulk.

Moreover, the sensitivity range of FSRs may vary depending on their design, with some models responding to pressures as light as a few grams, while others can handle several kilograms. This versatility makes them suitable for both delicate tasks and demanding industrial applications. By offering a relatively low-cost solution for pressure sensing, FSRs have become an essential component in the electronic industry, driving innovation and enhancing functionality across numerous products.

This bar chart illustrates the response of a Force Sensitive Resistor (FSR) to varying levels of applied pressure. As pressure increases, the resistance of the FSR decreases, affecting the voltage output in a circuit. The data shown represents voltage readings at different pressure levels.

Force Sensitive Resistors (FSRs) are highly versatile electronic components that change their resistance when a force or pressure is applied. These sensors are used across various applications due to their simplicity and effectiveness in detecting pressure, weight, and movement. In consumer electronics, FSRs are commonly employed in touch-sensitive devices, allowing users to interact with devices through varying levels of pressure instead of traditional buttons or switches. This capability enhances user experience by enabling more intuitive control systems.

In industrial settings, FSRs play a crucial role in weight measurement and monitoring systems. They can be integrated into conveyor belts to measure the weight of items for quality control or safety systems. Additionally, FSRs are utilized in healthcare applications, such as pressure mapping in medical beds, to prevent pressure ulcers by continuously monitoring the distribution of weight. Their ability to provide real-time feedback makes them invaluable in designing responsive systems in robotics and smart home technology. The adaptability and ease of integration of force-sensitive resistors significantly enhance the functionality and efficiency of electronic devices across various domains.

Force Sensitive Resistors (FSRs) are widely used in electronic applications due to their unique ability to change resistance in response to applied force or pressure. One notable advantage of using FSRs is their simplicity in design and implementation. They can easily be integrated into various circuits and sensors for touch-sensitive applications, making them a popular choice for human-computer interaction, wearable devices, and robotics. FSRs also provide a low-cost solution for pressure detection, which can be essential for budget-sensitive projects.

However, FSRs come with limitations that users should be aware of. Their sensitivity can vary with different force levels, resulting in inconsistent readings under certain conditions. Additionally, FSRs generally have a slower response time compared to other sensor types, which may not be suitable for applications requiring immediate feedback. Another limitation is their durability; prolonged exposure to excessive force can lead to degradation in performance over time.

Tip: When designing a project that incorporates FSRs, consider using calibration techniques to improve accuracy and reliability in your readings. Implementing software algorithms to smooth out sensor data can also enhance performance. Be mindful of the placement of FSRs in your design to minimize extraneous forces that could affect readings, ensuring the sensor is dedicated to intended interactions.

Force Sensitive Resistors (FSRs) are unique in their ability to detect varying levels of pressure or force applied to their surface. Compared to other types of sensors, such as piezoelectric sensors or capacitive sensors, FSRs offer distinct advantages and limitations. For instance, while piezoelectric sensors are excellent for detecting fast changes in pressure, they are less effective for continuous pressure measurement. In contrast, FSRs provide a straightforward analog signal that varies directly with the applied force, making them suitable for applications that require a general understanding of pressure levels rather than rapid changes.

When examining FSRs alongside capacitive sensors, notable differences arise in functionality. Capacitive sensors can detect the presence of objects without requiring direct contact and are sensitive to changes in dielectric materials. They are often used in touch-sensitive applications. However, FSRs excel in situations where direct pressure measurement is crucial, such as in applications involving soft materials or dynamic touch interfaces. This direct relationship between pressure and resistance change in FSRs allows for diverse applications ranging from medical devices to consumer electronics, showcasing their versatility in the electronic sensor landscape.