Nitrile gaskets are essential components widely utilized in various industrial applications, primarily due to their excellent resistance to oil, fuel, and other chemicals. As industries continue to evolve, the demand for high-performance sealing solutions has surged. According to a report by MarketsandMarkets, the global gasket market is projected to reach USD 17.6 billion by 2025, driven by the increasing need for enhanced sealing capabilities and durability in manufacturing processes.

A Nitrile gasket, made from a synthetic rubber compound, is particularly suitable for applications where exposure to petroleum-based fluids and harsh operating conditions is prevalent. Industry studies indicate that the Nitrile material exhibits superior performance in temperatures ranging from -40°F to 212°F (-40°C to 100°C), making it ideal for automotive, aerospace, and industrial machinery applications. As organizations prioritize reliability and efficiency, the adoption of Nitrile gaskets continues to grow, positioning them as a vital component in modern engineering and manufacturing practices.

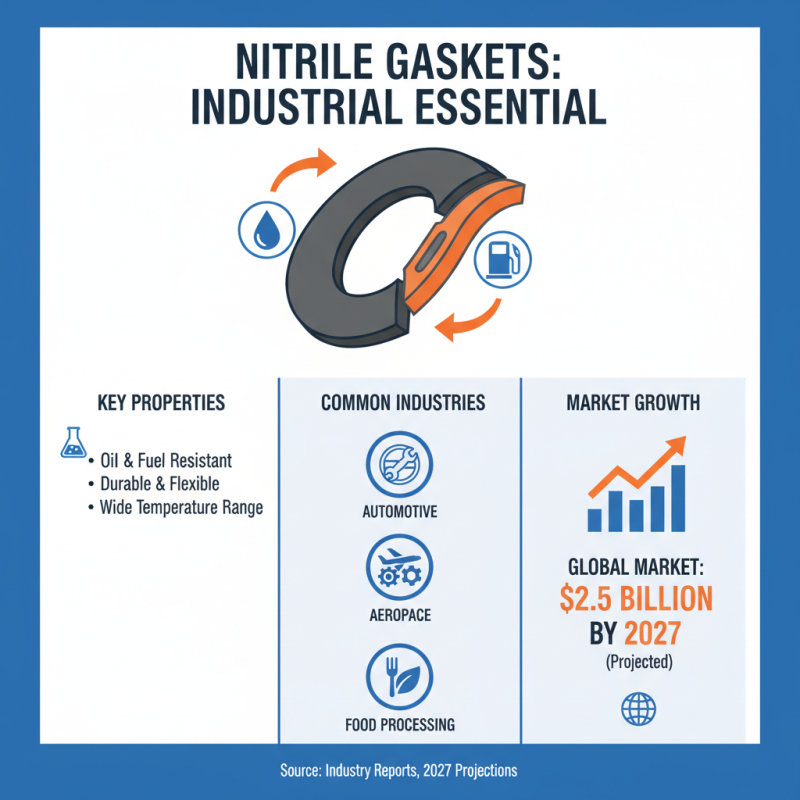

Nitrile gaskets, also known as NBR gaskets, are essential components in many industrial applications, renowned for their excellent resistance to oil, fuel, and other chemicals. Composed primarily of acrylonitrile and butadiene, nitrile rubber boasts a high level of durability and flexibility, making it a preferred choice in sectors such as automotive, aerospace, and manufacturing. According to a recent market analysis by the Global Materials Institute, the demand for nitrile gaskets is projected to grow at a CAGR of 4.6% through 2028, driven by increasing automation and the need for efficient sealing solutions.

The composition of nitrile gaskets plays a critical role in their performance characteristics. The percentage of acrylonitrile in the formulation can vary, usually ranging from 18% to 50%, which directly influences the gasket's resistance to petroleum-based fluids and its temperature tolerance. A study published in the Journal of Elastomeric Materials indicates that while NBR exhibits outstanding compressive strength and tear resistance, modifications in its formulation can enhance its performance against particular solvents and temperatures. This adaptability allows nitrile gaskets to cater to diverse environments, ensuring reliable sealing in demanding industrial processes.

Nitrile gaskets are essential components in various industrial applications due to their unique physical and chemical properties. One of the key attributes of nitrile rubber, also known as NBR, is its excellent resistance to oil and fuel, making it a favored choice in automotive and manufacturing sectors where exposure to hydrocarbons is common. This property ensures that nitrile gaskets maintain their integrity and effectiveness, preventing leaks and ensuring proper sealing under challenging conditions.

Another significant characteristic of nitrile gaskets is their durability in both high and low-temperature environments. They typically operate effectively in temperatures ranging from -40°F to 250°F, allowing them to be utilized in a diverse range of industrial settings, including food processing and chemical manufacturing. Additionally, nitrile gaskets exhibit good resilience and flexibility, which helps them conform to the surfaces they seal, further enhancing their sealing performance and longevity. Their combination of oil resistance, temperature tolerance, and mechanical strength makes them an indispensable choice for sealing solutions across numerous industries.

Nitrile gaskets, also known as nitrile rubber gaskets, are essential components commonly used in various industrial applications due to their excellent oil and fuel resistance. In manufacturing, these gaskets are particularly useful in automotive, aerospace, and food processing sectors. According to industry reports, the global market for nitrile rubber is projected to reach approximately $2.5 billion by 2027, reflecting its widespread utilization and growing demand across multiple industries.

One of the most common applications of nitrile gaskets is in sealing engine components within vehicles. They play a crucial role in preventing leaks and ensuring optimal performance under high temperatures and pressures. Additionally, in the food processing industry, nitrile gaskets are favored for their ability to withstand exposure to oils and fats, making them ideal for use in machinery where hygienic conditions are paramount. The chemical properties of nitrile rubber also allow it to perform effectively in environments where contact with petroleum-based products is frequent.

Tip: When selecting nitrile gaskets, ensure to consider factors such as temperature range, chemical exposure, and compatibility with application-specific conditions to enhance performance and durability. Regular inspections and timely replacements can also prevent system failures and improve maintenance efficiency in industrial settings.

Nitrile gaskets are widely used in various industrial applications due to their impressive performance metrics, particularly longevity and temperature resistance. Longevity is a crucial factor for gaskets, as their primary function is to maintain sealing integrity under mechanical stress and extreme conditions. Nitrile rubber exhibits excellent wear resistance and is able to withstand a wide range of operational cycles without significant degradation, making it an ideal choice for applications such as automotive, manufacturing, and oil processing. Depending on the formulation, nitrile gaskets can last for several years, thus minimizing the need for frequent replacements and reducing operational costs.

Temperature resistance is another key attribute of nitrile gaskets. These gaskets can withstand temperatures ranging from -40°F to 250°F (-40°C to 120°C), which allows them to function effectively in both low and high-temperature environments. This temperature resilience ensures that the gasket maintains its structural integrity and sealing capabilities, even when subjected to thermal expansion or contraction. It is this combination of longevity and temperature resistance that makes nitrile gaskets a reliable choice for industrial applications where consistent performance is critical to the overall efficiency and safety of equipment.

| Property | Value | Typical Applications | Notes |

|---|---|---|---|

| Material Composition | Nitrile Rubber (NBR) | Automotive, Oil & Gas, Heavy Machinery | Good resistance to oils and fuels |

| Temperature Range | -40°C to 100°C | Hydraulic Systems, Chemical Processing | Temperature limits may vary by specific formulation |

| Longevity | 5-10 Years | Flange Sealing, General Gasketing | Depends on environmental conditions and applications |

| Compressive Strength | 10-20 MPa | Hydraulic and Pneumatic Seals | High resistance to deformation |

| Chemical Resistance | Medium | Fluid Transport, Pump Sealing | Not suitable for strong acids and polar solvents |

Nitrile gaskets, composed of a synthetic rubber, are increasingly favored in various industrial applications due to their excellent resistance to oil, fuel, and other chemicals. These gaskets exhibit strong compressibility and recovery, making them ideal for sealing in environments where there is a significant temperature range or pressure variation. According to a recent market analysis by Grand View Research, the global gasket market, including nitrile options, is expected to reach USD 12 billion by 2027, driven by the growing automotive and oil and gas industries. Nitrile gaskets provide a reliable sealing solution, particularly in applications where traditional materials may fail due to chemical exposure.

In comparison to other gasket types, such as neoprene and silicone, nitrile gaskets offer superior abrasion resistance and tensile strength. Neoprene gaskets, while known for their weather resistance, often do not perform as well in high-temperature or oil-rich environments. On the other hand, silicone gaskets are often more flexible and endure higher temperatures, but they can be less effective against hydrocarbons. A comparative study published in the Journal of the American Society of Mechanical Engineers highlights that nitrile gaskets outperform neoprene and silicone in applications involving petrochemical exposure, demonstrating a significant reduction in failure rates. As industries look for dependable sealing solutions, nitrile gaskets are standing out as a versatile and effective choice.