In the rapidly evolving landscape of technology, pressure sensors have become integral to various modern applications, from automotive systems to industrial automation. Among the multitude of options available, Thin-Film Pressure Sensors stand out for their unique advantages. Dr. Emily Carter, a leading expert in the field of sensor technology, remarks, "The precision and reliability of Thin-Film Pressure Sensors are transforming how industries monitor and control critical processes."

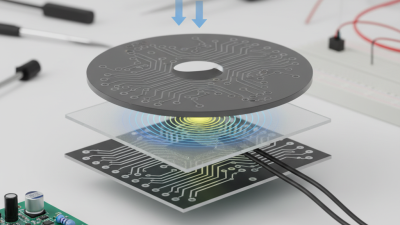

These sensors utilize a thin film of material that responds to pressure changes with remarkable sensitivity and accuracy. This development provides a significant leap forward from traditional pressure sensors, enabling engineers and designers to create more compact, efficient, and responsive systems. Furthermore, their robustness in diverse environmental conditions makes Thin-Film Pressure Sensors an appealing choice for a wide range of applications, including medical devices, aerospace, and industrial machinery. As industries continue to prioritize efficiency and effectiveness, understanding the benefits of Thin-Film Pressure Sensors will prove essential for those looking to optimize their applications in the modern technological era.

Thin-film pressure sensors have emerged as vital components in industrial automation systems, offering numerous advantages that enhance operational efficiency and accuracy. One of the primary benefits is their compact design, which allows for easy integration into various equipment and machinery. This space-saving feature makes them particularly valuable in environments where real estate is limited, enabling manufacturers to design more sophisticated and compact systems without compromising performance.

Another significant advantage of thin-film pressure sensors is their high sensitivity and accuracy. These sensors are capable of detecting minute changes in pressure, which is essential for maintaining optimal process conditions in industrial applications. This level of precision is critical for processes such as fluid control, monitoring gas levels, and ensuring the safety of equipment.

Additionally, their robust construction enables them to withstand harsh industrial environments, including extreme temperatures and corrosive substances, thus ensuring long-term reliability and reduced maintenance costs. As industries continue to evolve, the integration of thin-film pressure sensors will play a crucial role in driving automation and improving overall operational performance.

Thin-film pressure sensors are revolutionizing pressure measurement applications across various industries due to their enhanced accuracy and sensitivity. These sensors leverage advanced fabrication techniques that allow for the creation of highly responsive measurement devices. A report from the International Society of Automation highlights that thin-film technology can achieve precision levels of up to 0.1% of full scale, significantly surpassing traditional pressure sensors which typically offer around 1-2% accuracy. This increased precision enables industries such as aerospace, automotive, and medical applications to ensure more reliable data collection and monitoring.

Additionally, the sensitivity of thin-film pressure sensors is a critical factor in their application. According to a market analysis by Research and Markets, these sensors can detect even minute pressure changes, with some capable of measuring pressure variations as small as 1 mBar. This superior sensitivity is vital in environments where detecting slight pressure fluctuations can lead to significant safety improvements and operational efficiencies. The ability of thin-film sensors to perform under challenging conditions, such as extreme temperatures and corrosive environments, while maintaining high accuracy and sensitivity continues to drive their adoption in modern applications, solidifying their role as a key technology in the future of pressure measurement.

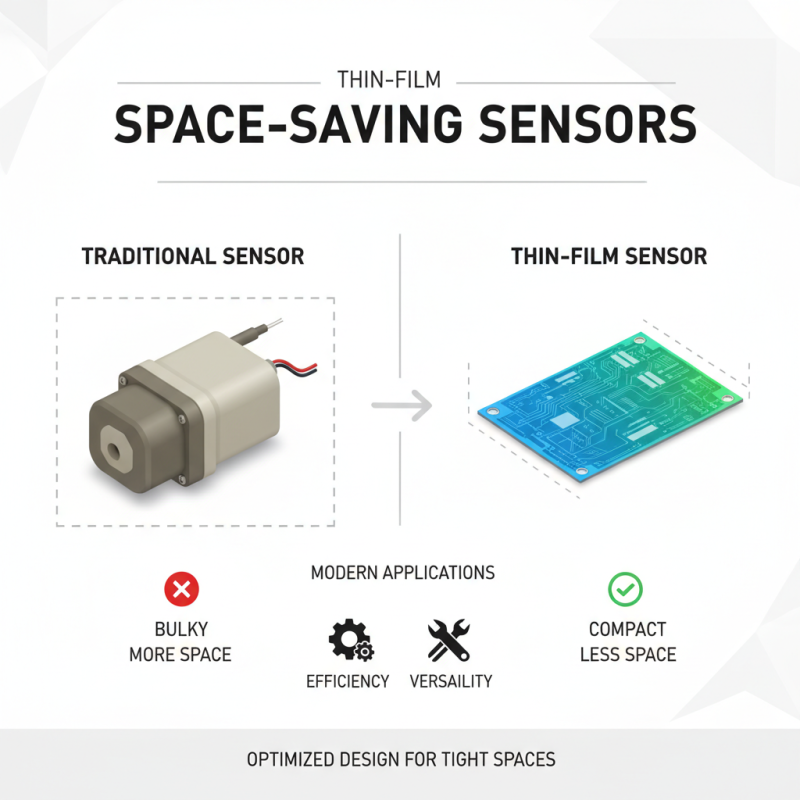

The compact design of thin-film pressure sensors offers significant space-saving advantages, making them ideal for modern applications that demand efficiency and versatility. Traditional pressure sensors tend to be bulkier, often requiring more extensive housing and installation space. In contrast, thin-film sensors are engineered to be lightweight and streamlined, allowing for integration into tight operational environments where space is a premium. This miniaturization enables engineers and designers to create more compact systems without compromising functionality or performance.

Moreover, the reduced footprint of thin-film pressure sensors facilitates innovative design strategies. With their small size, these sensors can be placed in locations that were previously inaccessible, enabling more precise measurements and enhancing overall system responsiveness. Additionally, the lightweight nature of thin-film technology helps decrease the overall weight of applications, which is particularly beneficial in sectors such as aerospace, automotive, and medical devices, where every gram counts. Consequently, the use of thin-film pressure sensors not only enhances design flexibility but also contributes to improved performance and efficiency in modern technology.

Thin-film pressure sensors are rapidly gaining attention in various modern applications, primarily due to their impressive resistance to harsh environments. These sensors are designed to withstand extreme conditions such as high temperatures, humidity, and corrosive substances, making them ideal for industries like aerospace, automotive, and oil and gas. Their robust construction ensures functionality even in the toughest settings, minimizing the risk of sensor failure and enhancing reliability in critical operations.

Furthermore, the durability of thin-film pressure sensors extends their lifespan, reducing the need for frequent replacements. This characteristic not only lowers maintenance costs but also promotes operational efficiency in environments where equipment must endure long periods without intervention. The ability to function effectively in challenging conditions signifies that these sensors can deliver accurate measurements where traditional sensors might falter. As industries continue to push boundaries in terms of environmental demands, the incorporation of thin-film pressure sensors becomes increasingly essential, ensuring that performance and precision are maintained without compromising on resilience.

Thin-film pressure sensors provide significant economic benefits, making them an attractive choice for various modern applications. According to a report by MarketsandMarkets, the global pressure sensors market is projected to grow from $12.9 billion in 2020 to $20.5 billion by 2025, driven largely by advancements in sensor technology, including thin-film designs. These sensors are not only lightweight and compact, but they also exhibit enhanced sensitivity and accuracy compared to traditional piezoresistive sensors—factors that contribute to cost savings in manufacturing and operational processes.

Furthermore, the manufacturing process of thin-film sensors allows for high-volume production with reduced material costs. A study by BCC Research indicates that the implementation of thin-film technology can lead to a reduction in production costs by up to 30%. This cost-effectiveness is crucial for industries like automotive and healthcare, where budget constraints are significant. By utilizing these sensors, companies can maintain competitive pricing without compromising on quality or performance, leading to a stronger return on investment over time.

| Benefit | Description | Economic Impact |

|---|---|---|

| Cost Efficiency | Thin-film sensors are cheaper to produce and install compared to traditional sensors. | Lower installation and maintenance costs |

| High Accuracy | Provides precise measurements, reducing error margins in critical applications. | Increases productivity and reduces waste |

| Compact Size | Their small footprint allows for integration into tight spaces and complex systems. | Facilitates innovations in design |

| Durability | Resistant to harsh conditions, leading to longer lifespan and lower replacement costs. | Reduces long-term operational costs |

| Versatility | Can be used in a variety of applications across different industries. | Expands market opportunities |