In the rapidly evolving landscape of modern technology, the demands for precision and efficiency have reached unprecedented levels. Central to meeting these demands is the innovation of the Thin-Film Pressure Sensor, a critical component that bridges the gap between traditional measurement techniques and the need for advanced functionality. These sensors have emerged as cornerstone devices in various industries, enabling enhanced monitoring and control in applications ranging from automotive systems to aerospace engineering.

The significance of Thin-Film Pressure Sensors lies not only in their compact design but also in their ability to deliver highly accurate pressure readings with minimal invasiveness. Their thin-film technology allows for better integration into existing systems, making them ideal for miniaturized applications where space and weight are critical factors. As industries strive for greater automation and data-driven decision-making processes, the role of these sensors becomes increasingly essential, paving the way for innovations in smart technologies.

As we delve deeper into the advancements spurred by Thin-Film Pressure Sensors, it becomes clear that their impact extends beyond mere measurements. They facilitate the development of intelligent systems capable of adapting to dynamic conditions, thus enhancing reliability and performance across diverse sectors. This exploration underscores the pivotal role these sensors play in shaping the future of technology, illuminating pathways toward greater efficiency and sustainability.

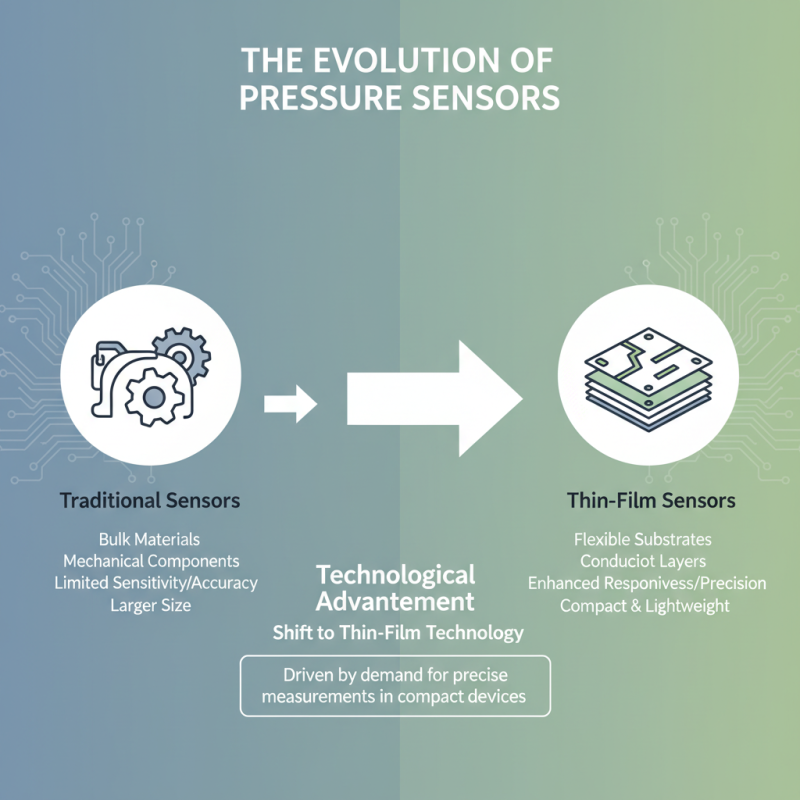

The evolution of pressure sensors reflects a remarkable journey of technological advancement, particularly with the introduction of thin-film technology. Traditional pressure sensors often relied on bulk materials and mechanical components, which could limit their sensitivity, accuracy, and overall performance. However, as industries began to demand more precise measurements in increasingly compact devices, a shift towards thin-film technology became essential. By utilizing layers of conductive materials that can be deposited onto flexible substrates, engineers were able to create sensors that are not only more responsive but also lighter and easier to integrate into modern electronic systems.

Thin-film pressure sensors leverage advancements in materials science to improve performance metrics significantly. The adoption of nanotechnology and innovative fabrication techniques allows for the production of sensors with heightened sensitivity and reduced power consumption. These characteristics make thin-film sensors ideal for applications in fields such as aerospace, automotive, and medical devices, where space constraints and stringent operational standards are prevalent. Furthermore, their durability and resistance to environmental factors enhance their reliability, making them indispensable in the ongoing development of smart technologies that increasingly rely on precise pressure measurements for optimal functionality.

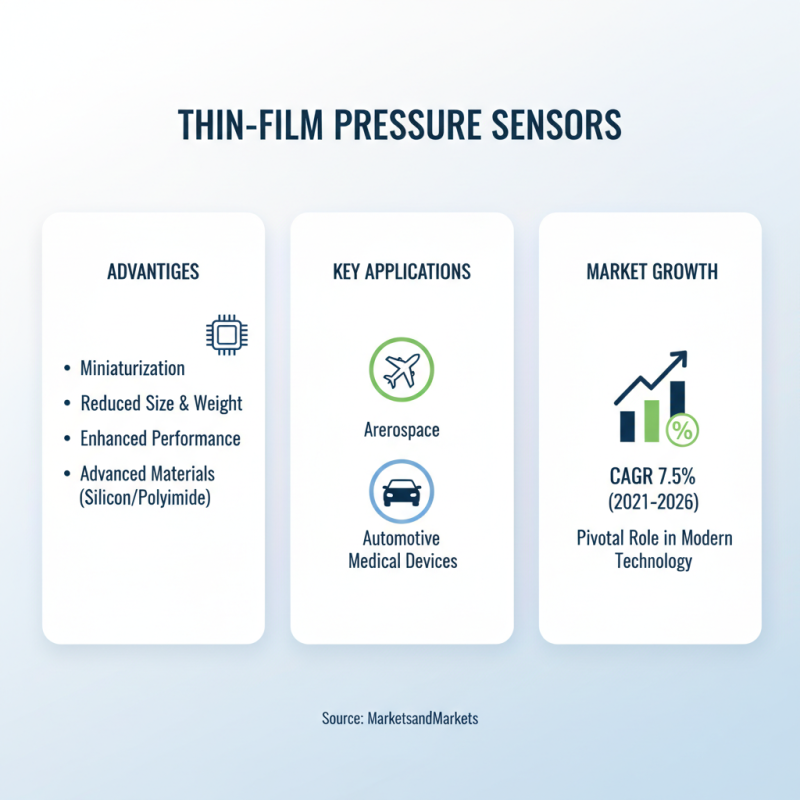

Thin-film pressure sensors have emerged as a pivotal technology in various industries due to their unique advantages. These sensors are renowned for their compact size and lightweight design, making them ideal for applications where space and weight are critical constraints. Their thin profile allows for integration into a wide range of devices, from medical instruments to automotive systems, enhancing functionality without compromising system performance. Additionally, their ability to provide precise measurements contributes significantly to the overall accuracy of the devices they are integrated into.

Another key advantage of thin-film pressure sensors is their robustness and resilience in extreme conditions. These sensors are designed to withstand harsh environments, making them suitable for industrial applications such as oil and gas, aerospace, and environmental monitoring. Their resistance to vibrations and temperature variations ensures consistent performance, which is essential for maintaining operational safety and reliability. Furthermore, the manufacturing processes involved in creating thin-film sensors lead to high levels of customization, allowing them to be tailored to specific application needs, enhancing their versatility across multiple domains.

Thin-film pressure sensors are increasingly recognized for their advantages over traditional counterparts as industries push towards miniaturization and enhanced performance. Unlike traditional pressure sensors, which often rely on bulky mechanical components, thin-film sensors utilize advanced materials like silicon and polyimide. This results in a significantly reduced size and weight, making them ideal for applications in aerospace, automotive, and medical devices. According to a report by MarketsandMarkets, the thin-film pressure sensor market is expected to grow at a CAGR of 7.5% from 2021 to 2026, underscoring their pivotal role in modern technology.

One of the most notable differences between thin-film and traditional pressure sensors is their sensitivity and accuracy. Thin-film sensors can achieve accuracy levels of up to ±0.1% full scale, thanks to their advanced fabrication techniques. This sensitivity allows for better performance in critical applications, such as in automotive safety systems and industrial automation, where precise measurements are crucial. Additionally, thin-film sensors demonstrate superior temperature stability, with temperature coefficients as low as ±0.005% per degree Celsius, making them a reliable choice for varied environmental conditions.

Tips: When selecting pressure sensors for your projects, consider the specific requirements of your application, such as size, sensitivity, and environmental resistance. Additionally, keep an eye on emerging technologies that may further enhance sensor performance and reliability, as these innovations could significantly impact your design choices in the near future. Always consult professional resources or industry publications for the latest data on sensor technology advancements.

Thin-film pressure sensors have emerged as a crucial component in various modern technological applications due to their small size, high sensitivity, and robust performance. These sensors are widely utilized in the automotive industry, where they enhance safety and efficiency by providing precise pressure measurements in tire monitoring systems, engine management, and fuel systems. Their lightweight design and ability to withstand extreme conditions make them ideal for integration into vehicles, contributing to the development of smarter, more reliable automotive technologies.

In the medical field, thin-film pressure sensors play a pivotal role in innovative health monitoring devices. They are integrated into wearable technology that tracks vital signs such as blood pressure and respiratory rates, delivering real-time data to healthcare providers. This capability not only enhances patient care but also supports telemedicine, allowing for better remote monitoring of patient health. The versatility of thin-film technology also extends to industrial applications, where these sensors are employed in process controls and safety systems, ensuring optimal operation and preventative maintenance in manufacturing environments. This innovation reflects the essential role that thin-film pressure sensors play in driving advancement across multiple sectors of modern technology.

The future of thin-film pressure sensor technology is poised for significant advancements driven by the increasing demand for precision and miniaturization in various applications. As industries such as automotive, aerospace, and healthcare continue to evolve, the need for sensors that can deliver accurate and reliable data in compact formats becomes critical. Emerging materials, such as micro-electromechanical systems (MEMS) and nanomaterials, are being explored to enhance the sensitivity and performance of these sensors, enabling their integration into smaller devices without compromising functionality.

Additionally, advancements in fabrication techniques are set to revolutionize the production of thin-film pressure sensors. Techniques such as 3D printing and advanced lithography are making it possible to create more complex sensor geometries while also reducing manufacturing costs. This democratization of technology allows for greater accessibility and customization in sensor design, catering to specific industry needs. Furthermore, the integration of IoT capabilities will lead to smarter sensors that can provide real-time monitoring and data analytics, thus paving the way for enhanced automation and control systems across a broad spectrum of applications.

| Feature | Value |

|---|---|

| Sensing Technology | Thin-film technology |

| Operating Range | 0 to 1000 bar |

| Temperature Range | -40°C to 125°C |

| Sensitivity | 2 mV/V/bar |

| Response Time | < 1 ms |

| Linearity | ±0.2% FS |

| Applications | Automotive, aerospace, industrial automation |

| Advancements | Integration with IoT, wireless technology |